industrial flooring services

Comprehensive Industrial Flooring Services

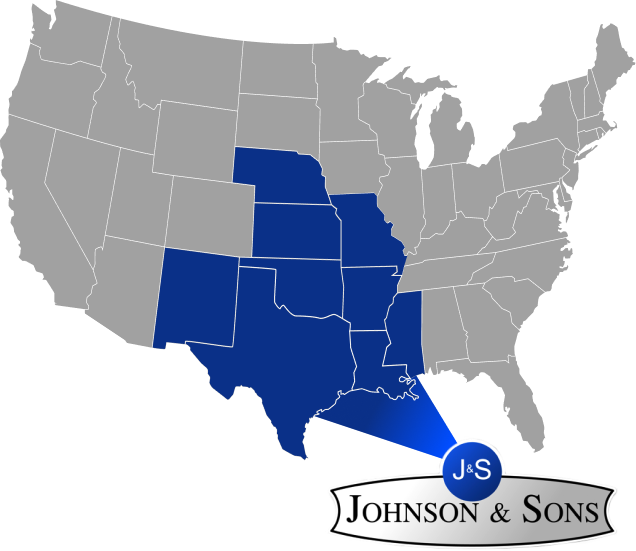

For over 35 years, Johnson & Sons has been the trusted name in advanced commercial and industrial flooring services. From durable epoxy coatings to polished concrete finishes, sealants, and containment applications, we provide tailored industrial flooring solutions that elevate businesses across the Southwest.

Our expertise spans a wide range of industries, including education, healthcare, senior living, manufacturing facilities, office, retail, data centers, and more. No matter the setting, our flooring systems are designed to meet your unique needs while maintaining peak productivity.

A professionally installed and well-maintained floor speaks volumes about your facility and brand. It reflects your commitment to excellence, reinforces your dedication to safety, and promotes a clean, healthy work environment for employees and customers alike. At Johnson & Sons, we’re here to ensure your flooring is more than a surface—it’s a statement of quality and professionalism.

More Than Just Epoxy Flooring

While many know us for our expertise in epoxy floor systems, Johnson & Sons goes beyond. As a full-service flooring contractor, we offer a complete range of industrial flooring services to meet all your industrial and commercial flooring needs.

- Sealers and Polishing

- Concrete Leveling / Overlay

- Underlayments

- Waterproofing

- Joint Sealants

-

wall coatings

(epoxy on walls) - microtopping

- polishing overlay

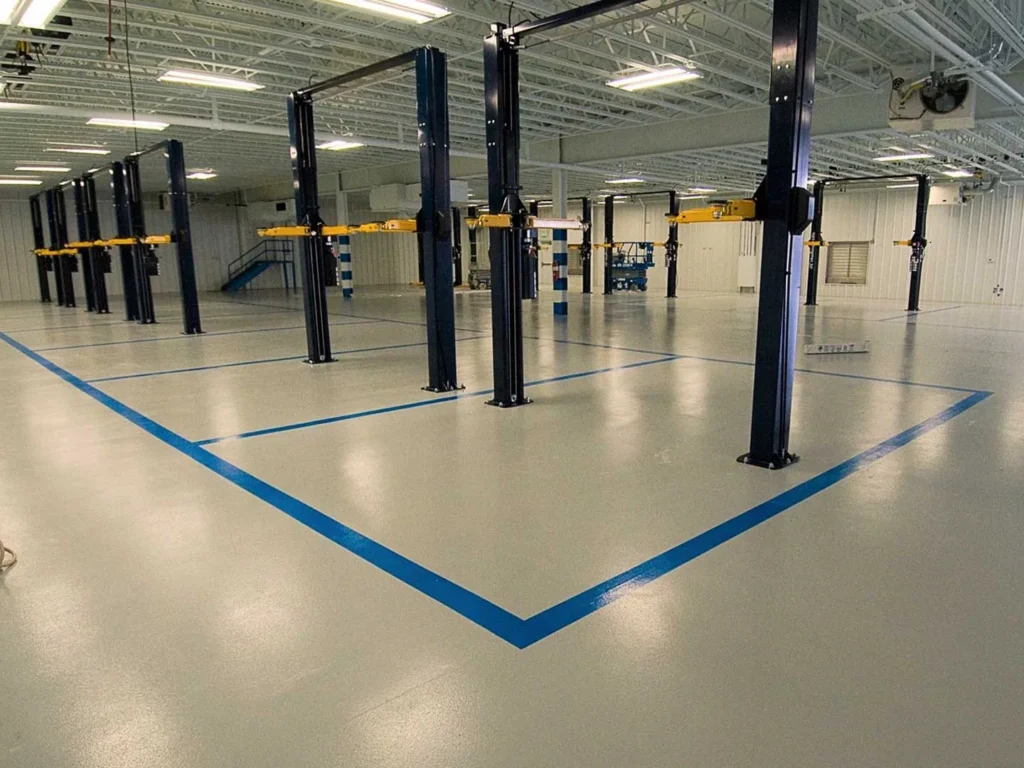

PAST industrial flooring PROJECTS

OWNER:

ROCKWALL ISD

INDUSTRY SECTOR:

EDUCATION

OWNER:

Walmart

INDUSTRY SECTOR:

INDUSTRIAL

OWNER:

DICKIES

INDUSTRY SECTOR:

RETAIL / OFFICE

OWNER:

VERONA

INDUSTRY SECTOR:

healthcare / senior living

OWNER:

RUDY’S BBQ

INDUSTRY SECTOR:

RESTAURANT

OWNER:

WHOLE FOODS

INDUSTRY SECTOR:

RETAIL

Industrial Flooring Services for Brands That Demand Excellence

For over 35 years, we’ve been the trusted partner for leading brands and GCs across the U.S., delivering superior industrial flooring services with a commitment to quality and professionalism. Our competitive pricing ensures value, but it’s the peace of mind we provide that sets us apart—offering dependable solutions you can trust every step of the way.

Expertise and Capacity for Large-Scale commercial and industrial Flooring Projects

With the ability to manage up to 25 crews daily across nine states, we handle even the most complex industrial and commercial flooring projects with efficiency. Our streamlined approach minimizes downtime, often completing installations in as little as 48 hours.